Gwintowniki maszynowe FENES-dobór parametrów skrawania

Gwintowniki maszynowe

|

|

|

|

|

|

|

|

|

|

Prędkość skrawania Vc[m/min] |

|

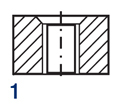

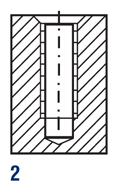

| Otwór przelotowy | |||||||||||

|

|||||||||||

| Otwór nieprzelotowy | |||||||||||

| Typ otworu | 1 | 2 | 1 | 2 | 1 | 2 | 1 | 2 | 1 | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Nakrój | B | C | B | C | B | C | B | C | B | ||

| 1 |

Stale niestopowe Rm 800 N/mm2 |

• | • | • | • | • | • | • |

10÷20* [1] 20÷50 |

||

| 2 |

Stale niestopowe i stopowe Rm 1000 N/mm2 |

○ | ○ | • | • | • | • | ○ |

10÷20* [1] 20÷50 |

||

| 3 |

Stale niestopowe i stopowe Rm 1200 N/mm2 |

• | • | • | • | 5÷20* [1] | |||||

| 4 |

Stale niestopowe i stopowe Rm 1400 N/mm2 |

• | • | 3÷10* [1] | |||||||

| 5 |

Stale nierdzewne i kwasoodporne [V2A] |

• | • | 2÷5* [1] | |||||||

| 6 |

Stale nierdzewne i kwasoodporne z podwyższoną zawartością chromu i niklu [V4A] |

○ | ○ | 10÷20* [1] | |||||||

| 7 |

Stale nierdzewne i kwasoodporne [V2A i V4A] |

○ | ○ | 10÷20* [1] | |||||||

| 8 | Stale szybkotnące | • | • | 5÷20* [1] | |||||||

| 9 |

Żeliwo szare [GG] |

○ | ○ | 10÷20* [2] | |||||||

| 10 |

Żeliwo sferoidalne, żeliwo ciągliwe [GGG, GT] |

○ | ○ | 20÷50* [2] | |||||||

| 11 |

Żeliwo wermikularne [GGV, GJV, CGI] |

○ | ○ | 20÷50* [2] | |||||||

| 12 | Aluminium, miedź, stopy miedzi | ○ | ○ | 30÷50* [1] | |||||||

| 13 | Stopy aluminium, stopy miedzi | ○ | ○ | 30÷50* [1] | |||||||

| 14 | Tworzywa termoplastyczne | ○ | ○ | ○ | ○ | ○ | ○ | 20÷30* [3] | |||

•Zastosowanie rekomendowane; ○Zastosowanie warunkowe

[1] Olej/emulsja, [2] Emulsja bez chłodzenia, [3] Bez chłodzenia lub powietrze

* Dla gwintowników oksydowanych: Vc=10-20m/min, dla pozostałych Vc=20-50m/min

Tabela materiałów obrabianych:

| Przedstawiciele wg DIN | ||||

|---|---|---|---|---|

| Rodzaj materiału | Grupa | Oznaczenie | DIN | Prędkość skrawania Vc[m/min] |

|

Stale niestopowe Rm 800 N/mm2 |

1 | St37-3 | 1.0116 |

10÷20 [m/min]

20÷50 [m/min] |

| St52-3 | 1.0507 | |||

| St60-2 | 1.0060 | |||

| StE 255 (S255N) | 1.0461 | |||

| StE 460 (P460N) | 1.8905 | |||

| StE 500 (S500N) | 1.8907 | |||

| C10 | 1.0301 | |||

| C22 | 1.0402 | |||

| C35 | 1.0501 | |||

| C40 | 1.0511 | |||

| GS-38 (GE200) | 1.0420 | |||

| GS-45 (GE240) | 1.0466 | |||

| GS-52 (GE260) | 1.0552 | |||

| GS-60 (GE300) | 1.0558 | |||

| 35S 20 | 1.0726 | |||

| 9S 20 | 1.0711 | |||

| 9SMn 28 | 1.0715 | |||

| 9SMn 36 | 1.0736 | |||

| 9SMnPb 28 | 1.0718 | |||

| 9SMnPb 36 | 1.0737 | |||

| 13Cr 3 | 1.7021 | |||

| 16MnCr 5 | 1.7131 | |||

| C15 | 1.0401 | |||

|

Stale niestopowe i stopowe Rm 1000 N/mm2 |

2 | Cf53 | 1.1213 |

10÷20 [m/min]

20÷50 [m/min] |

| Ck45 | 1.1191 | |||

| Ck55 | 1.1203 | |||

| Ck60 | 1.1221 | |||

| 15Cr 3 | 1.7015 | |||

| 15CrMo 5 | 1.7262 | |||

| 25CrMo 4 | 1.7218 | |||

| 32CrMo 12 | 1.7361 | |||

| 34Cr 4 | 1.7033 | |||

| 35CrMo 4 | 1.2330 | |||

| 35CrNiMo 6 | 1.6582 | |||

| 40Mn 4 | 1.1157 | |||

| 41Cr 4 | 1.7035 | |||

| 42CrMo 4 | 1.7225 | |||

| 47CrMo 4 | 1.2332 | |||

| C35 E | 1.1181 | |||

| C45 | 1.0503 | |||

| C55 | 1.0535 | |||

| C60 | 1.0601 | |||

| Cf35 | 1.1183 | |||

| Ck22 | 1.1151 | |||

| Ck25 | 1.1158 | |||

| 14NiCr 14 | 1.5752 | |||

| 16MnCr 5 | 1.7131 | |||

| Ck15 | 1.1141 | |||

|

Stale niestopowe i stopowe Rm 1200 N/mm2 |

3 | 39CrMoV | 1.8523 | 5÷20 [m/min] |

| 100Cr 6 | 1.3505 | |||

| 25CrMo 4 | 1.7218 | |||

| 30CrNiMo 8 | 1.6580 | |||

| 32CrMo 12 | 1.7361 | |||

| 34Cr 4 | 1.7033 | |||

| 40Mn 4 | 1.1157 | |||

| 41CrMo 4 | 1.7223 | |||

| 42CrMo 4 V | 1.7225 | |||

| StE690 V | 1.8931 | |||

| StE960 v | 1.8941 | |||

| 100Cr 6 | 1.2067 | |||

| 100MnCrW 4 | 1.2510 | |||

| 100V 1 | 1.2833 | |||

| 115CrV 3 | 1.2210 | |||

| 50CrV 4 | 1.8159 | |||

| 58CrV 4 | 1.8161 | |||

| 60WCrV 7 | 1.2550 | |||

| 90MnCrV 8 | 1.2842 | |||

| S10-4-3-10 | 1.3207 | |||

| X100 CrMoV 5 1 | 1.2363 | |||

| X165 CrMoV 12 | 1.2601 | |||

| X210 Cr 12 | 1.2080 | |||

| X210 CrW 12 | 1.2436 | |||

| X50 CrMoW 9 11 | 1.2631 | |||

| 35NiCrMo 16 | 1.2766 | |||

| 40CrMnMo 7 | 1.2311 | |||

| 45WCrV 7 | 1.2542 | |||

| 55NiCrMoV 6 | 1.2713 | |||

| 60NiCrMoV 12 4 | 1.2743 | |||

| X30WCrV 5 3 | 1.2567 | |||

| X30WCrV 9 3 | 1.2581 | |||

| X32CrMoV 3 3 | 1.2365 | |||

| X36CrMo 17 | 1.2316 | |||

| X38CrMoV 5 1 | 1.2343 | |||

| X40CrMoV 5 1 | 1.2344 | |||

| X42Cr 13 | 1.2083 | |||

| 14NiCr 14 | 1.5752 | |||

| 16MnCr 5 V | 1.7131 | |||

| 17CrNiMo 6 | 1.6587 | |||

| 31CrMo V 9 | 1.8519 | |||

| 34CnAINi 7 | 1.8550 | |||

| 35CrNiMo 6 | 1.6582 | |||

|

Stale niestopowe i stopowe Rm 1400 N/mm2 |

4 | 35CrNiMo 6 | 1.6582 |

3÷10 [m/min] |

| NiCr19 CoMo | 2.4973 | |||

| X5NiCrTi 26 15 | 1.4980 | |||

| 50CrV 4 | 1.8159 | |||

| 56NiCrMoV 7 | 1.2714 | |||

| X155CrVMo 12 1 | 1.2379 | |||

| Stale nierdzewne i kwasoodporne (V2A) | 5 | GX10CrNi 18 8 | 1.4312 |

3÷10 [m/min] |

| GX20Cr 14 | 1.4027 | |||

| GX5CrNi 19 10 | 1.4308 | |||

| GX8CrNi 13 | 1.4008 | |||

| X10Cr 13 | 1.4006 | |||

| X10CrNiS 18 9 | 1.4305 | |||

| X105CrMo 17 | 1.4125 | |||

| X12CrMoS 17 | 1.4104 | |||

| X12CrNi 17 7 | 1.4310 | |||

| X12CrS 13 | 1.4005 | |||

| X15Cr 13 | 1.4024 | |||

| X2CrNi 18 9 | 1.4306 | |||

| X2CrNiN 18 10 | 1.4311 | |||

| X20Cr 13 | 1.4021 | |||

| X20CrNi 17 2 | 1.4057 | |||

| X22CrNi 17 | 1.4057 | |||

| X10CrNiS 18 9 | 1.4305 | |||

| X3CrNiN 17 8 | 1.4319 | |||

| X30Cr 13 | 1.4028 | |||

| X39Cr 13 | 1.4031 | |||

| X46Cr 13 | 1.4034 | |||

| X5CrNi 18 12 | 1.4303 | |||

| X5CrNi 18 9 | 1.4301 | |||

| X5CrNi 18 9 | 1.4350 | |||

| X6CrAI 13 | 1.4002 | |||

| X6CrMo 17 | 1.4113 | |||

| X7Cr 13 | 1.4000 | |||

| X8Cr 17 | 1.4016 | |||

|

Stale nierdzewne i kwasoodporne z podwyższoną zawartością chromu i niklu (V4A) |

6 | GX5CrNiMo 19 11 | 1.4408 |

10÷20 [m/min] |

| GX5Cr 19 10 | 1.4552 | |||

| X1NiCrMoCuN 25 20 5 | 1.4539 | |||

| X10CrNiTi 18 9 | 1.4541 | |||

| X2CrMoTi 18 2 | 1.4521 | |||

| X2CrNiMo 17 13 2 | 1.4404 | |||

| X2CrNiMo 18 12 | 1.4435 | |||

| X2CrNiMoS 18 16 | 1.4438 | |||

| X2CrNiMoN 17 12 2 | 1.4406 | |||

| X2CrNiMoN 17 13 3 | 1.4429 | |||

| X2CrNiMoN 22 5 3 | 1.4462 | |||

| X3NiCrCuMoTi 27 23 | 1.4503 | |||

| X3CrNiMoN 27 5 2 | 1.4460 | |||

| X5CrNiCuNb 17 4 | 1.4542 | |||

| X5CrNiMo 17 1 | 1.4401 | |||

| X5CrNiMo 17 13 | 1.4449 | |||

| X5CrNiMo 17 13 3 | 1.4436 | |||

| X5CrNiNb 18 10 | 1.4546 | |||

| X5NiCrMoCuNb 20 18 | 1.4505 | |||

| X6CrNb 17 | 1.4511 | |||

| X6CrNiMoTi 17 12 2 | 1.4571 | |||

| X6CrNiNb 18 10 | 1.4550 | |||

| X6CrTi 12 | 1.4512 | |||

| X6CrTi 17 | 1.4510 | |||

| X12CrNiMo 12 | 1.4939 | |||

|

Stale nierdzewne i kwasoodporne (V2A i V4A) |

7 | X5NiCrTi26-15 | 1.4980 | 10÷20 [m/min] |

| X5CrNi 13 4 | 1.4313 | |||

| GX30CrSi6 | 1.4710 | |||

| X50CrMnNiNbN21-9 | 1.4882 | |||

| X55CrMnNiN20-8 | 1.4875 | |||

| X19CrMoNbVN11-1 | 1.4913 | |||

| X14CrMoS17 | 1.4104 | |||

| X4CrNiMo 16-5-1 | 1.4418 | |||

| X5CrNiCuNb 16-4 | 1.4542 | |||

| GXZ5CrNi 13-4 | 1.4317 | |||

| X20CrMo 13 | 1.4120 | |||

| Stale szybkotnące | 8 | S12-1-4-5 | 1.3202 | 5÷20 [m/min] |

| S18-0-1 | 1.3355 | |||

| S18-1-2-10 | 1.3265 | |||

| S18-1-2-5 | 1.3255 | |||

| S2-10-1-8 | 1.3247 | |||

| S2-9-1 | 1.3346 | |||

| S2-9-2 | 1.3348 | |||

| S2-9-2-8 | 1.3349 | |||

| S5-5-3 | 1.3344 | |||

| S6-5-2 | 1.3343 | |||

| S6-5-2-5 | 1.3243 | |||

| S7-4-2-5 | 1.3246 | |||

| SC6-5-2 | 1.3242 | |||

| Żeliwo szare (GG) | 9 | GG10 (EN-GJL-100) | 0.6010 | 10÷20 [m/min] |

| GG15 (EN-GJL-150) | 0.6015 | |||

| GG20 (EN-GJL-200) | 0.6020 | |||

| GG25 (EN-GJL-250) | 0.6025 | |||

| GG30 (EN-GJL-300) | 0.6030 | |||

| GG35 (EN-GJL-350) | 0.6035 | |||

| GG40 (EN-GJL-400) | 0.6040 | |||

| Żeliwo sferoidalne, żeliwo ciągliwe (GGG, GT) | 10 | GGG40 (EN-GJS-400-25) | 0.7040 | 20÷50 [m/min] |

| GGG50 (EN-GJS-500-7) | 0.7050 | |||

| GGG60 (EN-GJS-600-3) | 0.7060 | |||

| GGG70 (EN-GJS-700-2) | 0.7070 | |||

| GGG80 (EN-GJS-800-2) | 0.7080 | |||

| GTS55-05 | 0.8055 | |||

| GTW35-04 | 0.8035 | |||

| Żeliwo wermikularne (GGV, GJV, CGI) | 11 | GJV-300 | 20÷50 [m/min] | |

| GJV-400 | ||||

| GJV-30 | ||||

| GJV-40 | ||||

| Aluminium, miedź, stopy miedzi | 12 | AI99 | 3.0205 | 30÷50 [m/min] |

| AI99,9 | 3.0305 | |||

| AI99,9 R | 3.0400 | |||

| E-AI | 3.0257 | |||

| Sf-Cu | 2.0090 | |||

| CuZn20 (Ms80) | 2.0250 | |||

| CuZn30 (Ms70) | 2.0265 | |||

| CuZn37 | 2.0321 | |||

| G-CuSn 6 ZnNi | 2.1093 | |||

| G-CuSn 5 ZnPb | 2.1096 | |||

| Stopy aluminium, stopy miedzi | 13 | G-AISi12 | 3.2581 | 30÷50 [m/min] |

| G-AISi10 Mg | 3.2383 | |||

| G-AISi 12 (Cu) | 3.2583 | |||

| G-AISi 5 Mg | 3.2341 | |||

| G-AISi 6 Cu | 3.2151 | |||

| G-AISi 7 Mg | 3.2371 | |||

| G-AISi 8 Cu 3 | 3.2161 | |||

| G-AISi 9 Mg | 3.2373 | |||

| G-CuAI 10 Ni | 2.0975 | |||

| GD-AISi 12 (Cu) | 3.2982 | |||

| CuSn 6 Zn 6 | 2.1080 | |||

| Tworzywa termoplastycze | 14 | Polyamin | 20÷30 [m/min] | |

| Polystyrol | ||||

| Polyvynilchlorid | ||||

| Ultramid | ||||